This paper discusses techniques that will improve the service life and reliability of VRLA batteries. There are many facets that influence this and here we look at the most important items.

By improving the service life the reliability will be enhance. In a standby emergency battery system it is more important to improve the reliability rather than the service life. There are some parameters that will marginally reduce the service life but will enhance the reliability. Some care needs to be applied to obtain the correct balance.

It is imperative to start right if a long life and reliability are to be expected from the battery. To this end, competent persons should only carry out the installation. This is particularly important from a Health & Safety point. In this “time conscious world” that we live in we continually look to faster ways of carrying out tasks but this must not be at the expense of reliability. A VRLA battery is often an expensive item and the last line of defence and it is important to safeguard the Health & Safety and investment from the start. Without compromise, the following procedures should be followed at the installation stage: -

a) Upon receipt, move the consignment to a safe and secure location.

b) The storage area should be dry with an ambient temperature between +5ºC and 20ºC. The storage time is halved for every 10ºC increase in temperature. Consult the supplier for the maximum storage time that should not be exceeded.

c) When the battery is being installed, all individual cell or monobloc (unit) voltages should be measured and examine them for damage before they are installed into the enclosure or on the battery stand. Look for abnormalities such as low voltages and consult your supplier if in doubt about any values.

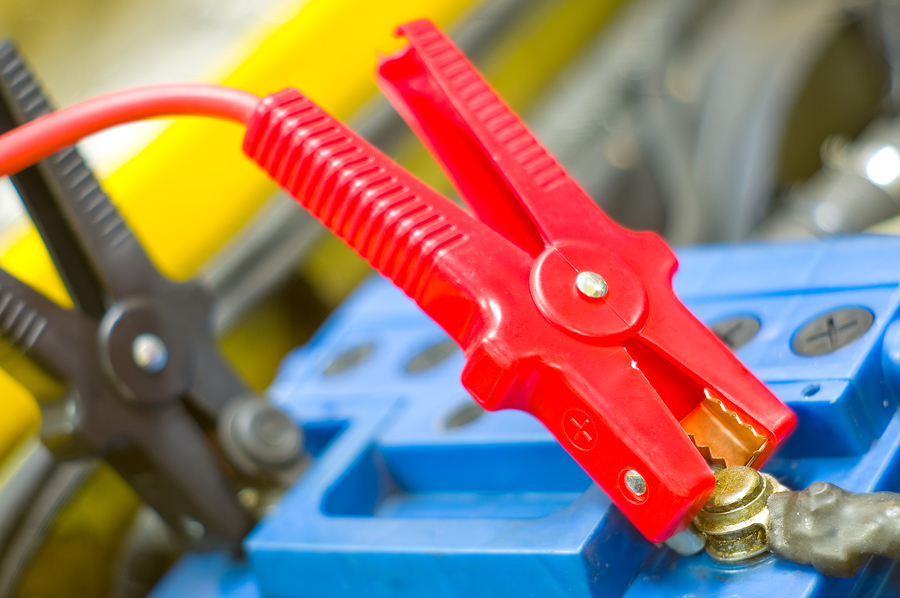

d) At the installation stage, ensure that the terminal connection faces are clean, free from corrosion and not damaged. Some manufacturers recommend a small quantity of corrosion resistant grease be applied to the terminals prior to assembly. Contact your supplier for further details. The units can now be positioned and connected. It is important to tighten bolts or nuts to the correct torque setting. Fires have been known to start because of incorrectly tightened connections.

e) Still isolated from the charger, but fully connected measure and record the open circuit voltages of all units. This is the “base” number used in the future. There is now a definitive voltage for the unit position in the string and its voltage that can be cross related in the future. Check that the typical unit voltage multiplied by the number of units reasonably matches the total string voltage. A 54 cell battery of VRLA cells may have a typical voltage of 2.13Vpc x 54 cells = 115V. If one cell is reverse connected, a voltage nearer 2.13Vpc x 52 = 111V will be measured.

Clearly a differential of 4V indicates a problem. The polarity should be checked if more than 2V difference is found between the typical unit voltage x the number of units and the voltage measured across the battery terminals.

f) The battery can now de connected to the charging source and all individual unit voltages should be measured and recorded typically about 1h after connecting to the charger. Also measure and record the charging voltage and if possible, the charging current. It is also a good idea to measure and record the typical unit temperature and ambient temperature round the battery.

g) It is recommended that a test discharge be carried out on the complete battery system before putting into service. This will not only prove that the battery can supply its designed power but will also prove that the charger is operating correctly when recharging.

It is important to set the float voltage to the correct value in accordance with the manufacturer’s recommendations for the battery temperature.

Significantly, the battery temperature may not be the same as the ambient temperature. If air conditioning is used to control the room temperature air circulation should be considered. It has been shown that in some instances, air conditioning may result in a temperature gradient across the battery by up to 5ºC and in some extreme cases more than this. An actual example of this was a 3-string battery system installed on a 6-tier stand where the bottom tier was 7ºC lower than the top tier. In this case the only solution was to revise the air conditioning. No adjustment of the float voltage could compensate for this difference. Typically, the temperature across the battery should be within ±2ºC of the average.

The charging source must be capable of maintaining the correct voltage within the recommended limits and preferably with temperature compensation. Ripple current should also be within the manufacturers limits. It has been shown that batteries fitted to some static UPS machines will “wear out” sooner than those connected to a typical “telecoms smoothed” charging system.

An overcharged battery will “wear out” faster and have a shorter life. However, the effects of undercharging may be even more dramatic because an undercharged battery may not supply the required power in the event of a critical supply incident and it may not be fully recharged following a discharge.

Float voltages should be checked at regular intervals and modern charging equipment often has this “built in” with the facility to send an alarm via the building management system.

The operating temperature has a significant effect on service life. Typically, for every 10ºC increase in battery temperature, the service life will be halved.

Temperature compensation of the charging voltage will mitigate some of the life lost if the temperature is greater than the optimum. However, when the battery temperature exceeds about 50ºC, depending on battery type, a significant reduction may take place, which the charging voltage may not be capable of countering. These include container-softening leading to loss of element compression because of swelling and dry out.

At the other end of the temperature spectrum, when the battery temperature is below 0ºC, the relationship between voltage compensation and temperature will not be linear and significant undercharging can result.

It is tempting to set the float voltage marginally low in the assumption that this will enhance the life because the charging current will be lower. Providing the voltage is set to within the manufacturers parameters, this is acceptable. However, a lower that recommended float voltage could lead to severe undercharging that will reduce life. Taken further, if the voltage is too low, the battery may not fully recharge after a discharge, leaving the available standby time lower than the design. Taken to the extreme, for short duration standby batteries, this can lead to no available protection because the voltage will collapse as soon as it is connected to the load.

It has often been claimed that the installation of battery monitoring will increase the life of the battery. In part this is true because faults may be detected before they become critical and suspect units may be replaced and the life of the system may be extended. The most important point in this subject is that the reliability will be enhanced.

Battery monitoring may be permanently connected or “hand held” and there are several different types available. Some measure the internal resistance whilst others are more sophisticated and measure impedance or conductance. This paper makes no recommendation for the type that should be used.

Battery manufacturers have their own recommendations for servicing batteries made by them and below are typical of what can be found in their literature. In all cases, the user should consult the supplier for specific requirements.

Monthly Service Recommendations.Ensure that the battery float charge voltage is within the recommended limits for the operating temperature. Record the voltage and date. See Additional Information below.

Three Monthly Inspection and Records.Ensure that the battery float charge voltage is within the recommended limits for the operating temperature. Record the voltage and date. See Additional Information below. With the battery connected to the charger operating in the normal float charge mode, measure and record all unit voltages, temperature, and as far as possible the charging current.

Six Monthly Service Recommendations.In addition to the Three Monthly Service Recommendations detailed above it is further recommended to carry out the following: -

If the battery has been subjected to vibration, check the unit connectors, inter-row, inter-tier and end connections for correct torque tightness.

Ensure the battery is in a clean and dry condition. For cleaning and drying, use only soft cotton cloths moistened is a solution of soap and water.

Examine all units for abnormalities.

Record all service requirements that have been carried out along with any abnormalities. Report all information to the person responsible for the battery and emphasise any abnormalities and recommendations.

Extended Period Service RecommendationsAfter a minimum of six months of satisfactory monthly inspections, the frequency of monthly requirements may be extended to three monthly.

Similarly, after six months (2 service operations) of satisfactory operation, the three monthly service recommendations may be extended to six months. The six monthly service recommendations may be extended to annually after one year of satisfactory operation.

Ensuring the integrity of standby power systems, whether this is for emergency lighting, security and fire alarms, or an uninterruptible power system (UPS), is of optimum importance.

In doing so, you will protect electronic data, computer equipment and even the occupants of your business premises in the event of an unexpected power outage. This is where batteries come into the equation - powering these devices will help to maintain building services and ensure that your business is protected.

So if you have discovered that your emergency lighting batteries need replacing, your UPS equipment isn’t providing backup power, or you simply want to consider your options for the future, take a look at five potential choices below.

C&D Technologies MRX RangeTo offer a sufficient and reliable level of power, you need a battery that’s going to last.

With the C&D Technologies MRX Range, this is exactly what you will get. The full MRX VRLA battery range is designed for a whole host of standby applications and offers high-quality and proven performance.

This style of battery offers maximum life and greater power during discharge, ensuring high current UPS output whilst making sure your emergency lighting operates correctly and complies with strict industry standards.

From the UPS12-100MRX 12V 34 Ah VRLA to the UPS12-600MRX 12V 147Ah VRLA model you can view our full product range of C&D Technologies MRX batteries here.

Enersys SBS RangeAnother reliable brand for emergency lighting batteries is Enersys, and in this example we’re looking at the SBS range.

With a vast amount of choice available and excellent performance quality, Enersys SBS batteries are a solid choice for your requirements.

The models within this product line have been designed with harsh environmental conditions in mind - resulting in a series of ultra-durable designs. Take a closer look at the Blue Box Batteries Enersys SBS range for standby applications.

Exide GNB Marathon RangeWith 16 options available in the Exide GNB Marathon product line on our site, these valve regulated lead acid batteries have been key players in the industry since 1996.

Suitable for long duration backup power, the Marathon range has evolved and developed over the years to remain at the forefront of technological innovation.

The new XL products reflect this by offering an increased power rating and shows that Exide are always looking to meet the demands and challenges faced by the industry and consumers alike.

Discover these robust and low maintenance batteries for yourself by clicking on the link above.

Fiamm FLB RangeA name synonymous with reliability, Fiamm FLB Highlite VRLA batteries are built on the back of a wealth of industry knowledge and expertise.

Development of the Fiamm range has taken place over 60 years and this is one of the main reasons for their continued success.

Fiamm don’t compromise on quality, so you are guaranteed optimal standby performance for your applications with the FLB range.

Here’s a full look at the Fiamm battery options.

Yuasa SWL RangeLastly on our list is the SWL range from Yuasa. These designs are perfect for standby applications, such as UPS, alarm systems and static inverter emergency lighting too.

Models in this line give up to 40% additional discharge capacity compared to the original NP range due to their enhanced design features, so you’ll get the power you need even for the most critical applications.

Head over to the Yuasa emergency lighting batteries page by clicking on the link above and view the products in more detail.

Contact Blue Box BatteriesSo there you have it, five potential options for replacing your emergency lighting batteries.

Remember that if need any technical assistance before you make a purchase, you can contact the friendly team here at Blue Box Batteries – we’ll be more than happy to help.

We stock a wide range of brands, models and accessories for all of your power supply needs, so don’t hesitate to get in touch today.

Due to the technological advancements made over the past 150 years, the battery can be found in a multitude of different applications today.

The essential function of each of these batteries, regardless of their size, shape, and chemical components, is to create power - and this in turn makes our lives a lot easier. So, amongst all of the different types, what is it that makes the lead acid design so popular?

Proven technologyFirst invented in 1859 by a French physician named Gaston Planté, the lead acid battery has come on leaps and bounds since its inception.

It was the first rechargeable battery for commercial use and today it can be found in a number of everyday items – such as toys, mobility equipment, starting applications, emergency lighting and UPS systems.

The technology has constantly evolved and been reinforced to become stronger and reliable than ever before, which is just one of the reasons why you’ll get optimum power with a lead acid battery.

Mass produced = affordableAlongside the fact that this type of battery is reliable and durable, it’s also mass produced too, which means that it’s affordable.

As this style of battery has many functions in the modern world, more than just a handful of them need to be manufactured.

Combining strength and long-lasting power with a design that’s affordable to produce and purchase makes the lead acid battery even more beneficial and efficient.

Low self-dischargeWhen you buy a battery, you want one that’s going to retain power and last a long time without having to charge it more often than not.

The lead acid battery fits into this category as it has a low self-discharge rate and is one of the lowest available in rechargeable battery systems.

This means that after a full charge, you will get the power you need for a substantial amount of time compared to other battery types available.

100% recyclableOn top of the physical power of the battery, this design also has an environmental advantage in that it’s 100 percent recyclable.

So, when your battery finally does come to an end, it can be recycled and put to good use in the future – maybe even to make another new battery!

Low maintenanceFinally, the sealed lead acid battery is low maintenance and doesn’t require any water top ups or electrolyte to fill.

Once it’s charged and added to your application or device, you can leave it alone and let it give you the power you need without having to worry about any additional upkeep.

It really is one of the best batteries around and thanks to history, development, and science it’s certainly made our lives a lot easier to manage.

Purchasing a lead acid batteryRemember, with a lead acid battery you will get premium power.

For more information please visit the batteries page on the Blue Box Batteries website.

Should you need further help or assistance finding the lead acid battery you require, please contact us directly.

Batteries are an integral part of lives. Wherever you go, and whatever you're doing, there are likely to be batteries in operation within a few feet of where you’re stranding.

Of course, there are some obvious examples, such as those in mobile phones and laptops. However, there are many other batteries that operate almost undetected, and some that provide back-up power in the event of a major failure of electricity supply. There are also many battery sizes on the market that are used to power different types of equipment.

So, with this in mind here’s a quick Blue Box Batteries guide to just some of the different types of batteries that you can purchase.

Small Sealed Lead Acid BatterySmall sealed lead acid batteries, otherwise known as an SSLA battery, usually come in 6V or 12V form. Other voltages do exist but are less common.

The SSLA battery is constructed of multiple lead plates connected together and immersed in a sulphuric acid solution. The acid is held in place against the plates via an absorbed glass mat material known as AGM. Using this process, 2V cells are formed. These cells are then connected to form battery blocks.

These batteries are for the best part sealed, with exception to a one way valve which allows gas to escape in the event of accidental overcharging. They can also be fully operated when positioned on their side.

SSLA batteries have a hugely successful design and can be found in every day equipment. Examples of this include single point emergency lighting, fire alarms, mobility scooters, desktop uninterruptible power supplies (UPS), parking meters, and a whole host of applications where a power source is required when mains electricity is not available.

PROS: Affordable technology, 100% recyclable, standard fitment sizes.

CONS: Can be heavy when compared to the equipment they are installed in, sensitive to temperatures.

Valve Regulated Lead Acid BatteryUsing the same chemistry as the small sealed lead acid batteries, valve regulated lead acid batteries (VRLA) are larger than their SSLA counterparts.

These batteries are able to cope with large high current applications and are commonly found in applications such as mid to large UPS, static inverter emergency lighting, large alarm systems and telecommunications equipment.

These products come in a wide range of power ratings and various fitment sizes and can be connected in series and parallel to form a battery system to suit the particular needs of the equipment that they’re being installed into.

VRLA batteries have become the most commonly used battery type for standby equipment, providing backup power to offices, data centres and manufacturing plants in the event of power outage.

In terms of shape and size, most VRLA batteries have a top terminal arrangement with a positive and negative terminal situated on each end of the battery. However there are exceptions in the form of front terminal batteries, which originated from the telecoms industry, where batteries were required to fit a standard 19” rack system.

Front terminal batteries are very narrow, generally sized so that 4 x 12V blocs can be fitted in series to form a 48V battery string in a single row. This then fits a 19” telecoms rack, where the terminals are fitted to the narrow front end of the battery to enable connection in the system without reaching over the battery as you would do with a standard top terminal battery version.

Not only do front terminal batteries have an advantage in terms of fitment in these systems, but the placement of the terminals makes ongoing maintenance much more convenient and safe as voltage measurements can be taken quickly and simply.

Whilst originally designed for telecoms applications, the advantages of front terminal batteries are more often used today in other standby power applications too. PROS: High current capacity, low maintenance, reliable and proven technology, 100% recyclable.

CONS: Heavy, sensitive to ambient temperatures.

Gel BatteryGel batteries are very similar to AGM batteries as above, though the electrolyte is suspended in gel silica rather than absorbed glass matt.

Due to the nature of these batteries, when compared to AGM they can boast greater resistance to vibration, shock and temperature extremes. As a result, they can commonly be found in motorised applications, such as boats and vehicles. They are also considered superior for deep discharge applications and were originally popular for using in mobility scooters, however improvements in AGM, including cyclic capacity and affordability have made this much less so over recent years.

PROS: Deep discharge capacity, high tolerance to vibration.

CONS: Expensive, can be sensitive to overcharging.

Nickel Cadmium BatteryNickel cadmium batteries, also known as NiCd or NiCad batteries are a popular form of rechargeable batteries and can be found in a large variety of shapes and sizes.

As implied in the name, the chemical construction of this battery consists of nickel oxide, hydroxide and metallic cadmium. These batteries are highly cyclic, providing in excess of 500 cycles and are commonly found in power tools, emergency lighting (both single point and in older inverter units). Nowadays however these are being replaced by newer technologies, such as Nickel Metal Hydride and Lithium due to their superior cyclic capacities and because they suffer less ‘memory effect’ compared to NiCad.

In terms of standby equipment, NiCad batteries were once very popular for heavy industrial use and some larger products provided a very high service life (around 20 – 25 years). However, this is now largely being phased out in favour of VRLA batteries which provide cost savings and provide a much more environmentally friendly solution against Nicad. NiCad batteries can still be found in old emergency lighting inverter units.

PROS: Long lasting, tolerates deep discharge.

CONS: Not environmentally friendly, improved technologies available for many applications.

Lithium BatteryLithium batteries offer the benefit of good cyclic capacity together with being very light. This type of battery is normally found in low power applications, such as phones, laptops and other computer equipment. Over recent years the technology has improved and can also be found in mobility applications such as electric bikes, golfing equipment and small end mobility scooters.

The main disadvantage to using lithium batteries is that the technology is still quite expensive when compared to other solutions, though hopefully as demand continues this will improve over time.

PROS: Very light, good cyclic capacity.

CONS: Expensive, can be difficult to transport in large quantities.

More InformationThanks for taking the time to read our guide on the different battery types. We hope you’ve learnt something and it’s proven to be useful.

Remember that batteries come in a range of different sizes, shapes and volts for a whole host of different purposes. If you do require further information then please contact Blue Box Batteries today.

When it comes to convenience, the battery has given us so much. From the calculator to the car and the motorbike to the mobile phone, these modern inventions would be nothing without a battery to power them. Batteries are great beyond a shadow of a doubt, but they do have one inconvenient downside - they run out.

The good news is that the life of most batteries can be extended with a little care and know how. Let's take a look at how you can get more out of your motorbike, lawnmower and mobility scooter batteries and not only save yourself money but also the inconvenience of a drained battery when you least expect it.

1. Always choose a good quality batteryWhen looking for a rechargeable battery it is important to select the best quality battery that your money can buy. It's true that you get what you pay for and when you choose a low quality, low cost battery, you can expect it to degrade very quickly.

For example, you might notice that you need to charge your battery more often or that it refuses to charge at all after a while. In contrast, a decent and reliable battery will last longer and provide more power with fewer charges as a result.

When it comes to looking for a suitable battery for your appliance, device or machine, don’t forget that a low cost battery won’t be as efficient.

2. Extending the life of your motorcycle batteryNo other vehicle can compare to a motorbike when it comes to freedom, power and speed rolled into one. So the last thing you'll want is to be stuck on the hard shoulder with a flat battery in the rain.

The first way to ensure your battery doesn't let you down is to choose the right battery for your particular bike. Incompatible batteries can wear out much faster so it is important that you check your owner's manual or ask your local garage or supplier to find and fit the right battery.

You should also ensure that your battery is kept fully charged. If you ride every day this shouldn't be difficult. Consult the manual or ask your battery supplier for further information if you need assistance.

3. Get more from your lawnmower batteryIf you are lucky enough to own a sit-on lawnmower, we’re guessing you have quite a large lawn to maintain. Don't risk running out of juice halfway through mowing the lawn when looking after your battery will ensure it charges and takes you to the end of the job.

Never fully discharge your lawnmower battery as this can significantly reduce its storage capacity. If you have a 3 stage charger on your mower, it will automatically stop the recharging process once the battery is fully charged and switch to a low ‘trickle charge’ where there is no need to disconnect the battery. However, if you have a ‘constant current’ charger it is important to remove your battery from the charger once it has been fully charged to avoid any damage.

Regularly check your cord, charger and battery to ensure they are in good working order and store your battery according to the advice in your owner's manual.

4. Mobility scooters and battery lifeDon't risk your mobility scooter running out of power when you need it the most. Normal battery life will depend on a number of factors, including the frequency of use and charging, the length of discharge, and the temperature at which the battery is being stored when not in use.

It is recommended that a mobility scooter battery is charged every day after it’s been used. Most mobility scooter chargers are sized to charge the battery, from discharged, in around 7-10 hours - also referred to as an ‘overnight charge’. This might not always be possible to achieve due to your own commitments, but if you look after your battery now, it will serve you well in the future.

5. If in doubt get the manual outYour owner's manual will be able to give you the best advice on battery care no matter what the device, appliance or type of battery.

Good quality batteries should give you years of reliable use but that life cycle does largely depend on the frequency they are being used and the care and attention they are given. When looked after properly, your batteries will give you a good run for your money and help you to avoid the frustration and expense of premature failure.

For further battery advice, contact Blue Box Batteries today.

Battery image from Bigstock.

- 1

- 2

Latest Headlines

Bulk Orders

Discounted prices are available for bulk orders, please contact us to discuss your requirement.