From April 2016 through to May 2016 Fiamm have been in the process refreshing the FLB, FIT and SLA series of VRLA standby batteries, which has included a change in box colour, product codes and updating the battery label. The following offers a description of the changes for each type.

FIAMM FLB BATTERY.Battery boxes for this type have now changed from solid grey box and lid to a dark blue box and grey lid. In physical size, terminal type, build standard and operational terms the battery is equivalent and completely compatible with previous models. To identify the new models the suffix of ‘P’ has now been included into the product code, for example the ‘12FLB350’ has now been rebranded as the ‘12FLB350P’.

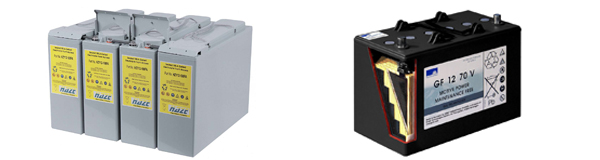

Please see the following image showing the old and new FLB battery.

The product label has also been refreshed to offer greater brand and range visibility together with additional technical information such as recommended float voltage and watts per cell rates at 15 minutes. Connection torque is also included on the label, which will assist in ensuring correct installation and on going maintenance.

New products have also been added as part of this programme offering a greater choice for high Ah mono blocs. These include the 12FLB700P 12V 710Ah and 12FLB800P 12V 792Ah and the 6FLB800P 6V 792Ah, which have been developed and designed for suitability in high discharge applications such as UPS, Telecommunications, Rail applications and similar.

Roll out of the new models have been scheduled as follows –

Fiamm 12FLB100P – April 2016 Fiamm 12FLB150P – May 2016 Fiamm 12FLB200P – March 2016 Fiamm 12FLB250P – March 2016 Fiamm 12FLB300P - April to May 2016 Fiamm 12FLB350P – April to May 2016 Fiamm 12FLB400P – April to May 2016 Fiamm 12FLB450P – April to May 2016 Fiamm 12FLB540P – February 2016 Fiamm 12FLB700P – Current Fiamm 12FLB800P – Expected May 2016Once the roll out is complete, previous ‘solid grey’ models will no longer be available.

FIAMM SLA BATTERY.As one of the most long-standing and successful series of the Fiamm battery catalogue, the SLA has also been subject to revision in order to suit today’s DC power market and common OEM demands.

Whilst retaining the traditional solid blue colour, some models have been redesigned to meet with universal box sizes found in todays industry.

It should be noted that box sizes for some models will differ from historical types and this should be accounted for when replacing like for like product codes in pre existing cabinets and racking systems. Products affected by changes in physical design feature prominently within the 26Ah to 180Ah spectrum, we will be advising of these changes on each specific SLA product page, showing both old and new data sheet information to ensure compatibility. As always, should you require advice regarding a specific project then please do contact us directly to discuss.

An example of the SLA product modernisation is shown in the image below, it includes the upgraded labelling offering clear product information.

FIAMM FIT BATTERYExpected later in 2016, the evolution of the FIT products continues with the introduction of new power ratings, with particular reference to the new 12FIT151 with compact dimensions designed to suit the needs of clients requiring a high energy density within 19 inch telecoms cabinets. Additional launches will also include the 12FIT201, which will offer a 12V 200Ah battery solution within the same physical dimensions of the 12FIT180.

As seen with the FLB series, the FIT battery box will be blue with a grey lid and the label will follow suit with the FLB and SLA in providing good brand and product information with technical specification and performance description relevant to each battery.

The history of the VRLA battery goes back to the early 1930’s. However, the term VRLA was not introduced until the 1980’s. Originally they were known as “sealed” batteries but following a number of serious incidents the more appropriate term of Valve Regulated Lead Acid (VRLA) battery took over.

Today we have two distinct types of VRLA batteries; those with gelled electrolyte (GEL) and those with absorbent glass mat (AGM) separators, which hold most of the acid.

The first VRLA batteries were in fact 2-volt cells and nothing like the multi-cell monoblocs or large capacity single cells we see today. They were “laboratory” types used for portable radio applications. By mixing fine silica with dilute sulphuric acid a thixotropic gel electrolyte was produced. Over time this partially dries out producing fisher cracks that allows oxygen to pass to the negative plates and gas recombination to take place. These original types had poor gas recombination efficiency and were designed to be spill resistant. They were not regarded as gas recombination products. There is evidence that the earliest “mat” batteries appeared about the same time and used separators made from felt, which held the acid. These were “sealed” with simple plugs when discharged and the plugs were removed when charging. Again, these were regarded as non-spill rather than recombination types. They were used for aircraft application when conventional “wet” batteries were not acceptable in aerobatic activities.

It can be reasonably argued that Otto Jache who was working for the German battery manufacturer Sonnenschein developed the modern GEL battery in 1957. (left) The GEL product was considered to be better for cycling applications and more vibration tolerant than the wet product equivalent. Later, Otto Jache and Heinz Schroeder developed the design for high capacity cells and multi cell monoblocs. GEL cells and monoblocs use a conventional separator similar to those used in “wet” cells. These early products had a simple valve to prevent leaks.

As the GEL product became more popular and as cell technology developed it was realized that the water usage was very low and cells did not dry out very quickly. With a one-way valve set at about 2psi good gas recombination was achieved. This was in the very early days when gas recombination was not fully understood. It was discovered that at the end of the charge cycle when oxygen is being produced at the positive electrode, it is capable of passing through the gel, which had develop fisher cracks as it dried out slightly. Oxygen is rapidly attracted to the negative electrode, which is highly charged spongy lead. Upon contact with the negative electrode, oxygen changes the spongy lead to lead-oxide, and being in contact with the electrolyte water is produced.

Today, GEL cells are available in small capacity monoblocs of only a few Ah up to large capacity single cells of over 4000Ah. The largest cells may be mounted vertically or horizontally. There resistance to vibration makes then inherently good where a seismic resistant product is preferred.

The early “mat” batteries were few and none were regarded as very good. Investigations moved towards a sealed nickel-cadmium product but the real objective was to produce a “maintenance free” lead-acid battery at a lower cost. It was not until the early 1960’s that real studies into a viable maintenance free mat separator battery took place.

It was well understood that oxygen would recombine with the negative electrode in nickel-cadmium cells and also in the gelled electrolyte products. However, the problem was to develop a separator that would allow sufficient acid to be present within the cell and would also allow gas to pass through it to the negative electrode where gas recombination would occur.

In 1967, John Devitt and Donald McClelland began researching small cylindrical lead-acid cells with spirally wound electrodes. At that time, they were working for Gates Energy Products, a USA company, who were the largest manufacturer of rubber belts and hoses in the world and wanted to go into the battery business. By the end of the year they showed the first “Gates D Cell” to the Gates board of directors. In 1971, the newly formed company Gates Energy Products was offering the D cell and the X cell recombination products to the world market.

These cells were the first to use a microfiber glass separator and the term we know today as “absorbent glass mat” (AGM) was born.

The secret was in the separator, which held sufficient electrolyte for the electro-chemical reactions to work but would also give sufficient “open area” for the transportation of oxygen to the negative electrode.

Development of the product continued with a change to a more corrosion resistant grid alloy, higher plate to separator compression ratios and a better understanding of the internal gas pressure on recombination efficiency.

One of the most interesting demonstrations of the characteristics of the early “D” cell was to connect a paper clip between the positive and negative terminals. The short circuit current would quickly result in the paper clip glowing red-hot before melting. The current flowing during short circuit was over an order of magnitude greater than that from an alkaline product and this was already substantially higher than the best high discharge current available from the GEL or “wet” product. This high current superiority is one of the advantages of the AGM when compared with the GEL product.

The product was known then, as it is now, as the Cyclon battery.

Development continued and manufacturing spread. A relatively small Company called Varley Batteries in the UK was manufacturing aircraft batteries and Gates wanted part of the business. Varley adopted the Cyclon technology and offered a prismatic version of the AGM product to several aircraft manufacturers. Notably BAe 125 and 146 business jets used the product along with the Harrier the AV8B and some F16 variants as alternatives to the NiCd batteries previously used.

To increase high performance and durability, rolled-punched grid technology is often used in the production of VRLA AGM product. Plates can be less than 1mm thick with correspondingly thin separators. The high rate currents from the batteries made today surpass that available from any other type of lead acid battery of comparable volume or capacity. The vibration resistance is also superior to conventional “wet” batteries and similar to the GEL battery.

Development of both GEL and AGM batteries continues. The specific gravity has been increased in mat batteries to enhance the voltage profile and offer better long rate capacity whilst additions of carbon to the plate structure of GEL batteries means that the high current discharge characteristics are substantially better than only a few years ago.

Undoubtedly, development of the VRLA battery will continue because lead-acid batteries are more cost effective when compared to any other electrical storage system for industrial applications.

Today there are many battery manufacturers around the world producing GEL and AGM products. Some are low cost types built down to a price whilst others are state of the art built to exacting international standards.

Power protection is essential for modern business, this can be achieved by installing a UPS to ensure building facilities and IT equipment remain online during mains power failure. But what is a UPS and how does it work?

UPS is an abbreviation of ‘uninterruptible power supply’ and is exactly that, a device that provides uninterrupted power in the event of mains failure. Equipment such as computers, servers and a range of IT infrastructure apparatus can be affected by power quality and failure, if a server is not properly shut down without warning then this can result in the loss of valuable data. If a business operates tills or similar equipment then a mains power fault without a UPS in place will result in an immediate shutdown of equipment needed to complete transactions and provide essential customer support.

It is not just business that rely on a back up power source such as a UPS, many public services such as hospitals, airports and train services all have UPS in place to provide clean reliable power even when mains power is not present.

UPS come in a huge range of sizes, with rating descriptions as follows:

VA (volts ampere) small range UPS, often for single computers, tills or small office environments.

kVA (kilo volt ampere) mid range and the most common UPS rating description used in various environments such medium offices, supermarkets and such like.

MVA (mega volt ampere) large range UPS systems, often found in datacentres and other large power environments.

HOW IS THE POWER SUPPLIED?The vast majority of UPS will be reliant on back up power from a connected battery source, the most common type of battery used in UPS is lead acid technology. Small UPS will utilise sealed lead acid batteries and larger UPS will most commonly use valve regulated lead acid batteries to provide power. The battery is often the heaviest and largest component of a UPS, and it is not unusual for the battery to account for more than 40% of the cost. For further information on battery types, please refer to our previous blog post A Guide to Large Rechargeable And Industrial Battery Types.

As a basic description, a UPS will be incorporated between the mains power and the building load, providing filtered power to any equipment connected to the UPS. The main components of a UPS are as follows –

Rectifier – The rectifier will convert the AC power (alternating current) from the mains to DC power (direct current), this is necessary for the batteries, which operate only on DC power.

Battery – In the event of a power outage the batteries will provide the power to the electrical load connected to the UPS. This may be computer equipment, servers, or any other item being protected by the UPS.

Inverter – The inverter will convert the DC power from the batteries back to AC power required by the buildings electrical load. The inverter will switch to the batteries in the event of a power outage by means of a static switch.

The UPS will also incorporate power filtering to ensure the power supplied is ‘clean’ and free of surges, lags, spikes and any number of power issues which can effect sensitive IT equipment.

It is worth noting that not all UPS rely solely on batteries for backup power, some larger UPS will use a flywheel system rather than batteries, these types of UPS are known as ‘rotary’ UPS.

DOESN’T A GENERATOR PROVIDE THE SAME FUNCTION?In the event of a mains failure, a UPS will provide power in what is effectively ‘zero time’ meaning the electrical load being supported will continue to operate without interruption. A generator will take much longer to start up and generate enough power to take over the load, as a guide around 5 – 10 minutes is common though this can vary depending on the system implemented.

Often a generator and UPS system will be incorporated together to provide power protection. Once the mains supply has failed, the UPS will initially take over the load using battery as the power source, when the generator is ready to support the load the UPS will then switch over and use the power from the generator instead of the battery.

Power provided by the generator will continue to run via the UPS as this will ensure a clean, filtered power supply as generator power can be unclean by comparison and not suitable for IT loads.

HOW LONG DOES A UPS PROVIDE POWER FOR?The UPS battery run time or ‘autonomy’ will depend on the battery installed, this can range from 5 minutes, enough time to start a generator or shutdown IT equipment safely, or several hours. Obviously the longer the autonomy required the larger the battery will need to be. Large installations can include numerous cabinets or racks dedicated to UPS batteries and will weigh many tonnes though small UPS may be no larger than a shoebox. A UPS supplier will tailor the battery design to suit client requirements.

CONTACTING BLUE BOX BATTERIESBlue Box Batteries are specialists in providing battery systems for UPS ranging from small single phase units for home or small office use, to large systems protecting data centres, public services and large power environments.

For the best advice and assistance call us on 02381 789197.

If you're looking to protect your business' information, data and content no matter what the situation, then an Uninterruptible Power Supply is the ideal solution.

Take a look at our latest informative infographic to find out how a UPS can save your business admin, time and money.

Embed this Infographic on your website:

Source: Blue Box Batteries

Retaining information, content and data is hugely important for the success of any business, regardless of its size.

With this in mind, consider a scenario whereby your company was no longer able to gain access to this critical information. Whilst the primary job of a data centre is to house this type of content, the effects of losing power can be extremely detrimental to your business.

Let’s take a look at five of these potential risks in greater detail.

Financial ImplicationsFirst and foremost, limited or restricted access to your data and content can put a halt to business operations.

The knock-on effect of this means that even simple day-to-day tasks will be compromised, as you can no longer provide an optimum service. This can result in your company suffering financially until the problem is resolved.

As the saying goes, time is money, and this is even more relevant where business is concerned, so you’ll want to ensure you avoid this situation occurring at all costs.

Decreased ProductivityAnother fundamental aspect of a successful business is a productive and efficient workplace. Losing data centre power can restrict staff access to the information they need in order to do their job properly.

In this scenario, it’s likely that productivity will decrease, which again can have a damaging effect on generating new business and increasing revenue.

This is where you need to make sure you have a sufficient back-up plan to deal with these risks and restore business operations back to normal.

Un-retrievable DataLosing information even for a short period of time isn’t an ideal situation, so imagine if you couldn’t access this data ever again.

Without a sufficient back-up plan in place (such as the installation of UPS batteries), when the power fails, you run the risk of losing data for good.

If this information is un-retrievable, then your staff will have no option other than to accept that the data is gone, or alternatively spend additional time recreating the content they need.

This puts added pressure on your business, as resources aren’t being used to maximise efficiency.

Company DowntimeIf you lose data centre power then you will experience downtime across your business until the problem is fixed. This of course will be a different scenario if you have a back-up plan in operation.

Downtime can affect IT devices and technologies, which can lead to further issues for your company. When it comes to business, don’t compromise, or put yourself in a position where these risks can affect the day-to-day running of your organisation.

Instead, speak to a professional battery supplier to eliminate or reduce the risk factor of any of the above.

Contact Blue Box Batteries TodayBlue Box Batteries supply a range of UPS batteries to ensure that you never lose power and your data centres run smoothly at all times.

For more information on how to protect your company’s power and data, contact us today on 02381 789197 or get in touch with us via our website

Server image from Bigstock.

Many businesses up and down the country rely on a variety of IT equipment in their offices - such as servers and telecoms equipment. These centres are hugely important as they house and operate the information, communication technology or 'ICT' infrastructure that supports their company.

Depending on the size of your business, you might have an IT infrastructure that contains a cage of equipment, or on a larger scale, a whole room dedicated to multiple cabinets such as a data centre. These centres, servers and devices store important company data and content.

So, take a moment to think about the implications of losing this information if the power was to fail. This is where an uninterruptible power supply can help. Let's find out more.

Losing PowerWithout a sufficient uninterruptible power supply (UPS) system in operation, if the power fails and cuts off your existing IT infrastructure, your company could experience the following:

Lost or un-retrievable data, information and content

Downtime across your organisation effecting your existing IT devices

Damaging financial implications

Decreased staff productivity

As a business you'll want to do all you can to reduce the risk of a power outage occurring, to keep your data centres running and your company delivering the best results possible. Even if your data centre is housed externally, as opposed to in-house, there is still a risk of a minor or significant power outage if UPS batteries are not set up as a backup.

UPS BatteriesThe UPS battery powering your UPS will provide your business with the power you need in a scenario if the mains power for your data centre fails. Should the power fail, UPS are designed to take over from the mains supply straight away, effectively in 'zero time' - meaning that your data and content will remain accessible, safe and secure.

This is hugely beneficial for your company, as it allows you to continue to operate as normal, access all of the information you need, and maintain solid business relationships.

A data centre which is protected with UPS batteries will also allow your business to:

Stay in control

Enhance security

Manage risk

Without this setup, it's very difficult for your business to regain control after a disaster until the initial problem is resolved - which could take a number of hours.

Professional AdviceHere at Blue Box Batteries, we sell a vast range of UPS Batteries to help your business data centres run sufficiently in the event of a power failure.

Make sure that your data, content and information is secure at all times by purchasing the batteries you need today.

Contact the Blue Box Batteries team for further assistance on 02381 789197 or alternatively get in touch via our website.

- 1

- 2

Latest Headlines

Bulk Orders

Discounted prices are available for bulk orders, please contact us to discuss your requirement.